Datasheet

3D Model

ST319RAD Series

Chip Inductors for Critical Applications

ST319RAD Series combines the exceptionally high Q of an air core inductor with the rugged construction of a ceramic body component.

- Inductance values: 1.15 nH – 10.4 nH.

- Provides intermediate inductance values not available in Coilcraft’s 0603, 0402 or 0906 product families.

- Silver-palladium-platinum-glass frit terminations. Other terminations available at additional cost.

Specifications

Electrical specifications at 25°C.

| Part number 1 |

Inductance (nH)

2

(Tolerance: ± 5%) |

900 MHz | 1.7 GHz |

Q min

@ 500 MHz 3 |

SRF min (GHz) 4 | DCR max (Ω) 5 | Imax (A) | ||

|---|---|---|---|---|---|---|---|---|---|

| L typ | Q typ 3 | L typ | Q typ 3 | ||||||

| ST319RAD1N1JLZ | 1.15 | 1.2 | 40 | 1.2 | 136 | 25 | > 5.0 | 0.021 | 3.0 |

| ST319RAD2N6JLZ | 2.6 | 2.6 | 78 | 2.6 | 163 | 45 | > 5.0 | 0.026 | 2.0 |

| ST319RAD4N5JLZ | 4.5 | 4.5 | 103 | 4.7 | 155 | 50 | > 5.0 | 0.032 | 1.8 |

| ST319RAD5N0JLZ | 5.0 | 4.9 | 106 | 5.2 | 178 | 60 | > 5.0 | 0.032 | 1.6 |

| ST319RAD6N8JLZ | 6.8 | 6.9 | 101 | 7.4 | 172 | 60 | 4.7 | 0.035 | 1.8 |

| ST319RAD7N6JLZ | 7.6 | 7.4 | 109 | 7.9 | 137 | 60 | 4.4 | 0.035 | 1.5 |

| ST319RAD10NJLZ | 10.4 | 10.6 | 103 | 11.5 | 160 | 60 | 4.1 | 0.037 | 1.5 |

Notes

- When ordering, please specify termination and testing codes: e.g. ST319RAD10NJLZ.

- Inductance measured at 500 MHz using a Coilcraft SMD-A fixture in an Agilent/HP4286 impedance analyzer with Coilcraft-provided correlation pieces.

- Q measured at 500 MHz using an Agilent/HP4291A with an Agilent/HP16193 test fixture.

- SRF measured using an Agilent/HP8753D network analyzer and a Coilcraft SMD -D test fixture.

- DCR measured on a Cambridge Technology micro-ohmmeter and a Coilcraft CCF858 test fixture.

Termination:

- L = Silver-palladium-platinum glass frit.

- S = Tin-lead (63/37) over silver-palladium-platinum-glass frit. (Special Order, added cost)

- T = Tin-silver-copper (95.5/4/0.5) over silver-palladium-platinum-glass frit. (Special Order, added cost)

- R = Tin over nickel over silver-platinum-glass frit. (Special Order, added cost)

- P = Tin-lead (63/37) over tin over nickel over silver-platinum-glass frit. (Special Order, added cost)

- Q = Tin-silver-copper (95.5/4/0.5) over tin over nickel over silver-platinum-glass frit. (Special Order, added cost)

Testing:

- Z = Unscreened

- H = Group A screening per Coilcraft CP-SA-10001

Custom screening also available.

Environmental

Ambient temperature range:

–55°C to +125°C with Imax current.

Storage temperature range:

Component: –55°C to +155°C.

Tape and reel packaging: –55°C to +80°C.

Tape and reel packaging: –55°C to +80°C.

Maximum part temperature:

+155°C (ambient + temp rise).

Failures in Time (FIT) / Mean Time Between Failures (MTBF):

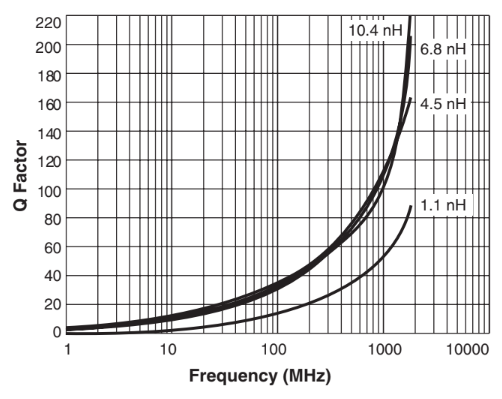

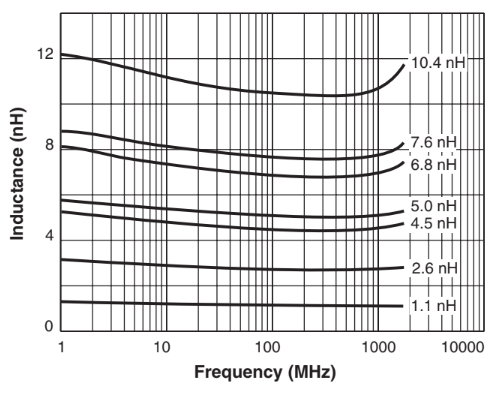

Performance curves

Typical Q vs Frequency

Typical L vs Frequency

General specification

Core Material:

Ceramic

Packaging:

2000 per 7′′ reel; Plastic tape: 8 mm wide, 0.23 mm thick, 4 mm pocket spacing, 1.27 mm pocket depth.

Temperature coefficient of inductance:

+25 to +155 ppm/°C.

Soldering/Washing

Moisture Sensitivity Level (MSL):

1 (unlimited floor life at <30°C / 85% relative humidity).

Resistance to soldering heat:

Max three 40 second reflows at +260°C, parts cooled to room temperature between cycles.

Refer to Soldering Coilcraft Components before soldering.