Datasheet

3D Model

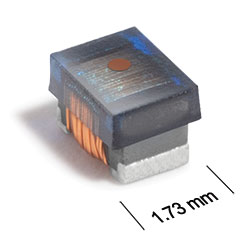

ST336RAM Series

Chip Inductors for Critical Applications

ST336RAM Series features ferrite construction for high current handling.

- Higher inductance values than ceramic 0805 inductors.

- Heavy gauge wire for low DCR.

- Matte tin over nickel over silver-platinum-glass frit terminations.

Specifications

Electrical specifications at 25°C.

| Part number 1 |

Inductance (µH)

2

(Tolerance: ±5%) |

Impedance typ (Ω) | Q min 3 | SRF min (MHz) 4 | DCR max (Ω) 5 | Imax (mA) | Color code |

|---|---|---|---|---|---|---|---|

| ST336RAM111JRZ | 0.11 @ 7.9 MHz | 370 @ 500 MHz | 14 @ 7.9 MHz | 1000 | 0.05 | 700 | Brown |

| ST336RAM681JRZ | 0.68 @ 7.9 MHz | 430 @ 100 MHz | 15 @ 7.9 MHz | 340 | 0.30 | 410 | Orange |

| ST336RAM102JRZ | 1.0 @ 7.9 MHz | 670 @ 100 MHz | 13 @ 7.9 MHz | 280 | 0.39 | 360 | Yellow |

| ST336RAM122JRZ | 1.2 @ 7.9 MHz | 860 @ 100 MHz | 15 @ 7.9 MHz | 300 | 0.64 | 260 | Brown |

| ST336RAM152JRZ | 1.5 @ 7.9 MHz | 1000 @ 100 MHz | 16 @ 7.9 MHz | 225 | 0.74 | 250 | Green |

| ST336RAM182JRZ | 1.8 @ 7.9 MHz | 1360 @ 100 MHz | 16 @ 7.9 MHz | 240 | 0.98 | 210 | Blue |

| ST336RAM222JRZ | 2.2 @ 7.9 MHz | 840 @ 50.0 MHz | 15 @ 7.9 MHz | 90 | 0.98 | 190 | Brown |

| ST336RAM272JRZ | 2.7 @ 7.9 MHz | 1050 @ 50.0 MHz | 15 @ 7.9 MHz | 80 | 1.16 | 190 | Violet |

| ST336RAM332JRZ | 3.3 @ 7.9 MHz | 1670 @ 50.0 MHz | 15 @ 7.9 MHz | 65 | 1.20 | 190 | Gray |

| ST336RAM472JRZ | 4.7 @ 7.9 MHz | 950 @ 25.0 MHz | 14 @ 7.9 MHz | 40 | 1.50 | 170 | Black |

| ST336RAM682JRZ | 6.8 @ 7.9 MHz | 450 @ 10.0 MHz | 14 @ 7.9 MHz | 28 | 1.90 | 150 | Brown |

| ST336RAM103JRZ | 10 @ 2.5 MHz | 740 @ 10.0 MHz | 14 @ 2.5 MHz | 18 | 2.20 | 130 | Red |

| ST336RAM153JRZ | 15 @ 2.5 MHz | 1300 @ 10.0 MHz | 13 @ 2.5 MHz | 15 | 4.25 | 90 | Yellow |

| ST336RAM223JRZ | 22 @ 2.5 MHz | 1620 @ 10.0 MHz | 13 @ 2.5 MHz | 15 | 6.70 | 75 | Green |

Notes

- When ordering, please specify termination and screening codes: e.g. ST336RAM223JRZ.

- Inductance measured at 0.1 Vrms, using Coilcraft SMD-A fixture in Agilent/HP 4286A impedance analyzer or equivalent with Coilcraft-provided correlation pieces.

- Q measured on Agilent/HP 4291A with Agilent/HP 16197A test fixture or equivalents.

- SRF measured using Agilent/HP 8753ES network analyzer or equivalent with Coilcraft SMD-D test fixture.

- DCR measured on a Keithley 580 Micro-ohmmeter or equivalent with a Coilcraft CCF858 test fixture.

Termination:

- R = Matte tin over nickel over silver-platinum-glass frit.

- Q= Tin-silver-copper (95.5/4/0.5) over tin over nickel over silver-platinum-glass frit. (Special order, added cost)

- P = Tin-lead (63/37) over tin over nickel over silverplatinum-glass frit. (Special order, added cost)

Screening:

- Z = Unscreened

- H = Coilcraft CP-SA-10001 Group A

- Screening performed to the document’s latest revision.

- Lot qualification (Group B) available.

- Custom testing also available.

- Country of origin restrictions available; prefix options G or F.

Environmental

Ambient temperature range:

–40°C to +85°C with Imax current.

Storage temperature range:

Component: –55°C to +100°C.

Packaging: –55°C to +80°C.

Packaging: –55°C to +80°C.

Maximum part temperature:

+100°C (ambient + temp rise).

Failures in Time (FIT) / Mean Time Between Failures (MTBF):

Performance curves

L vs Frequency

Q vs Frequency

Impedance vs Frequency

Physical characteristics

| A max | B max | C max | D ref | E | F | G | H | I | J | |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.090 | 0.068 | 0.060 | 0.020 | 0.050 | 0.016 | 0.040 | 0.070 | 0.040 | 0.030 | inches |

| 2,29 | 1,73 | 1,52 | 0,51 | 1,27 | 0,41 | 1,02 | 1,78 | 1,02 | 0,76 | mm |

General specification

Core Material:

Ferrite

Weight:

16.7– 18.0 mg

Packaging:

2000/7″ reel; Plastic tape: 8 mm wide, 0.23 mm thick, 4 mm pocket spacing, 1.6 mm pocket depth.

Soldering/Washing

Moisture Sensitivity Level (MSL):

1 (unlimited floor life at <30°C / 85% relative humidity).

Resistance to soldering heat:

Max three 40 second reflows at +260°C, parts cooled to room temperature between cycles.

Refer to Soldering Coilcraft Components before soldering.