Datasheet

3D Model

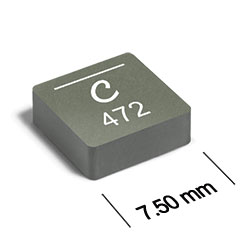

ML514PYA Series

High-Reliability Power Inductors

ML514PYA Series offers high current and very low DCR.

- High temperature materials allow operation in ambient temperatures up to 155°C.

- Passes vibration testing to 80 G and shock testing to 1000 G.

- Soft saturation makes them ideal for VRM/VRD applications.

- Tin-silver (96.5/3.5) over copper terminations.

Specifications

Electrical specifications at 25°C.

| Part number 1 |

Inductance (µH)

2

(Tolerance: ±20%) |

DCR (mΩ) 3 | SRF (MHz) 4 | Isat (A) 5 | Irms (A) 6 | |||

|---|---|---|---|---|---|---|---|---|

| typ | max | min | typ | 20°C rise | 40°C rise | |||

| ML514PYA161MLZ | 0.16 | 1.15 | 1.26 | 126 | 158 | 60.0 | 18.7 | 24.4 |

| ML514PYA301MLZ | 0.30 | 1.75 | 1.92 | 81 | 101 | 41.0 | 15.8 | 20.7 |

| ML514PYA601MLZ | 0.60 | 3.00 | 3.30 | 58 | 72 | 36.0 | 13.5 | 17.3 |

| ML514PYA102MLZ | 1.0 | 4.55 | 5.00 | 41 | 52 | 28.0 | 12.1 | 16.4 |

| ML514PYA152MLZ | 1.5 | 7.60 | 8.36 | 31 | 39 | 23.5 | 8.9 | 11.3 |

| ML514PYA222MLZ | 2.2 | 13.70 | 15.07 | 23 | 29 | 18.0 | 7.5 | 9.7 |

| ML514PYA272MLZ | 2.7 | 15.70 | 17.30 | 25 | 32 | 12.8 | 6.7 | 8.6 |

| ML514PYA332MLZ | 3.3 | 19.50 | 21.45 | 20 | 25 | 12.3 | 6.0 | 7.5 |

| ML514PYA472MLZ | 4.7 | 26.10 | 30.00 | 17 | 21 | 10.1 | 5.2 | 6.8 |

| ML514PYA562MLZ | 5.6 | 28.10 | 32.32 | 14 | 17 | 9.8 | 4.0 | 5.5 |

| ML514PYA682MLZ | 6.8 | 45.00 | 51.75 | 12 | 15 | 8.7 | 3.3 | 5.1 |

| ML514PYA822MLZ | 8.2 | 53.00 | 60.94 | 10 | 13 | 8.4 | 2.2 | 4.4 |

Notes

- When ordering, please specify screening code: e.g. ML514PYA822MLZ.

- Inductance tested at 100 kHz, 0.1 Vrms using an Agilent/HP 4192A.

- DCR measured using a micro-ohmmeter.

- SRF measured using an Agilent/HP 4395A or equivalent.

- DC current at 25°C that causes an inductance drop of 30% (typ) from its value without current.

- Current that causes the specified temperature rise from 25°C ambient. This information is for reference only and does not represent absolute maximum ratings.

Note:

Irms testing was performed on a 0.060” inch thick pcb with 4 oz copper traces optimized to minimize additional termperature rise. Temperature rise is highly dependent on many factors including pcb land pattern, trace size, and proximity to other components. Therefore temperature rise should be verified in application conditions.

Screening:

- Z = Unscreened

- Y = Unscreened (SLDC Option A)

- W = Unscreened (SLDC Option B)

- H = Group A screening per Coilcraft CP-SA-10001

- G= Coilcraft CP-SA-10001 Group A (SLDC Option A)

- D = Coilcraft CP-SA-10001 Group A (SLDC Option B)

Custom screening also available.

Environmental

Ambient temperature range:

–55°C to +105°C with Irms current.

Storage temperature range:

Component: –55°C to +155°C.

Tape and reel packaging: –55°C to +80°C.

Tape and reel packaging: –55°C to +80°C.

Maximum part temperature:

+155°C (ambient + temp rise).

Failures in Time (FIT) / Mean Time Between Failures (MTBF):

Performance curves

Typical L vs Frequency

L vs Current

General specification

Core Material:

Composite

Weight:

0.63 – 1.22 g

Packaging:

400 per 7″ reel Plastic tape: 16 mm wide, 0.33 mm thick, 12 mm pocket spacing, 3.0 mm pocket depth.

Soldering/Washing

Moisture Sensitivity Level (MSL):

1 (unlimited floor life at <30°C / 85% relative humidity).

Resistance to soldering heat:

Max three 40 second reflows at +260°C, parts cooled to room temperature between cycles.

Refer to Soldering Coilcraft Components before soldering.