Datasheet

3D Model

ST145RAP Series

Ceramic Chip Inductors

The ST145RAP Series has high inductance values, with twice the Q factor of thin-film technology inductors of the same size. Measuring just 0.58 x 0.46 x 0.46 mm, they are optimized for LTE Antenna matching.

- Higher L than other 0201 inductors.

- Twice the Q of thin-film multilayer technology.

- Optimized for LTE Antenna matching.

- Tin over nickel over moly-mag terminations.

Specifications

Electrical specifications at 25°C.

| Part number 1 |

Inductance (nH)

2

(Tolerance: ± 5%) |

900 MHz | 1.7 GHz | 2.4 GHz |

Q min

@ 250 MHz 3 |

SRF min (GHz) 4 | DCR max (Ω) 5 | Imax (mA) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| L typ | Q typ 3 | L typ | Q typ 3 | L typ | Q typ 3 | ||||||

| ST145RAP22NXJRZ | 22 | 21.8 | 36 | 22.7 | 52 | 24.2 | 62 | 14 | 3.50 | 0.75 | 140 |

| ST145RAP24NXJRZ | 24 | 23.8 | 36 | 24.9 | 53 | 27.1 | 56 | 14 | 3.50 | 0.93 | 130 |

| ST145RAP27NXJRZ | 27 | 26.9 | 35 | 28.2 | 47 | 30.5 | 55 | 14 | 3.20 | 1.03 | 125 |

| ST145RAP33NXJRZ | 33 | 33 | 35 | 35.4 | 45 | 39.6 | 49 | 14 | 3.00 | 1.14 | 120 |

| ST145RAP39NXJRZ | 39 | 39.4 | 35 | 42.7 | 43 | 49.5 | 45 | 14 | 2.75 | 1.55 | 100 |

| ST145RAP47NXJRZ | 47 | 47.6 | 35 | 52.8 | 43 | 64.3 | 41 | 14 | 2.60 | 1.70 | 95 |

| ST145RAP51NXJRZ | 51 | 51.9 | 35 | 58.3 | 44 | 71.5 | 44 | 14 | 2.75 | 1.85 | 90 |

Notes

- When ordering, please specify termination and screening codes: e.g. ST145RAP51NJRZ.

- Inductance measured at 250 MHz using a Coilcraft SMD-F fixture in an Agilent/HP 4982 impedance analyzer with Coilcraft-provided correlation pieces.

- Q measured using an Agilent/HP 4991A with an Agilent/HP 16197 test fixture.

- SRF measured using an Agilent/HP 8722ES network analyzer and a Coilcraft CCF1235 test fixture.

- DCR measured on a micro-ohmmeter and a Coilcraft CCF1099 test fixture.

Termination:

- R=Tin over nickel over moly-mag.

- P=Tin-lead (63/37) over tin over nickel over moly-mag.

- Q=Tin-silver-copper (95.5/4/0.5) over tin over nickel over moly-mag.

Screening:

- Z = Unscreened

- H = Coilcraft CP-SA-10001 Group A

- Screening performed to the document’s latest revision.

- Lot qualification (Group B) available.

- Custom testing also available.

- Country of origin restrictions available; prefix options G or F.

Environmental

Ambient temperature range:

–40°C to +85°C with Irms current.

Storage temperature range:

Component: –55°C to +125°C.

Tape and reel packaging: –55°C to +80°C.

Tape and reel packaging: –55°C to +80°C.

Maximum part temperature:

+125°C (ambient + temp rise).

Failures in Time (FIT) / Mean Time Between Failures (MTBF):

Performance curves

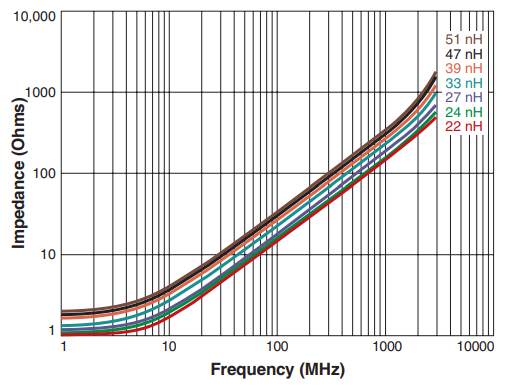

Impedance vs Frequency

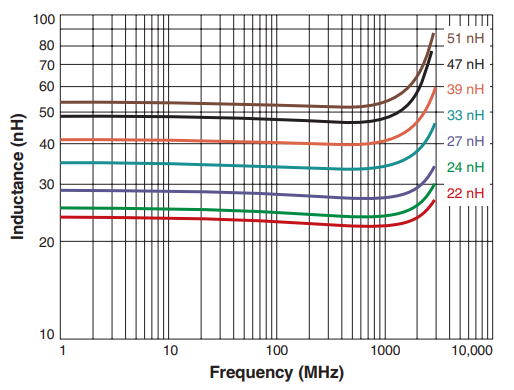

L vs Frequency

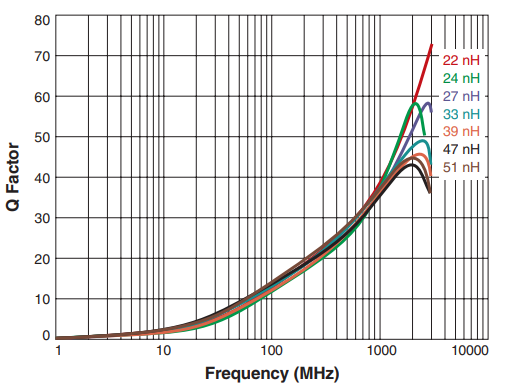

Q vs Frequency

General specification

Core Material:

Ceramic

Weight:

0.14 – 0.23 mg

Packaging:

2000 per 7″ reel. Paper tape: 8 mm wide, 0.68 mm thick, 2 mm pocket spacing.

Temperature coefficient of inductance:

+25 to +150 ppm/°C.

Soldering/Washing

Moisture Sensitivity Level (MSL):

1 (unlimited floor life at <30°C / 85% relative humidity).

Resistance to soldering heat:

Max three 40 second reflows at +260°C, parts cooled to room temperature between cycles.

Refer to Soldering Coilcraft Components before soldering.