Datasheet

3D Model

ST235RAQ Series

Chip Inductors for Critical Applications

ST235RAQ Series inductors offer up to 40% higher Q factor and 45% lower DCR than other 0402 series.

- 0402 ceramic wirewound chip inductor.

- 112 inductance values available from 0.8 nH to 120 nH, including 0.1 nH incremental steps from 2.8 nH to 10 nH.

- Up to 40% higher Q factor and 45% lower DCR than other 0402 series.

- Very high SRF – as high as 28.8 GHz.

- Matte tin over nickel over silver-platinum-glass frit terminations.

Specifications

Electrical specifications at 25°C.

| Part number 1 | Inductance (nH) 2 | Tolerance (%) 3 | 900 MHz | 1.7 GHz | 2.4 GHz |

Q min

@ 250 MHz 4 |

SRF min (MHz) 5 | DCR max (mΩ) 6 | Imax at 125°C (mA) 7 |

|---|---|---|---|---|---|---|---|---|---|

| Q typ 4 | Q typ 4 | Q typ 4 | |||||||

| ST235RAQN80_RZ | 0.8 | 5 | 54 | 62 | 110 | 18 | > 5000 | 25 | 600 |

| ST235RAQN90_RZ | 0.9 | 5 | 42 | 65 | 89 | 13 | > 5000 | 30 | 600 |

| ST235RAQ1N0_RZ | 1.0 | 5 | 41 | 66 | 91 | 14 | > 5000 | 45 | 460 |

| ST235RAQ1N2_RZ | 1.2 | 5 | 27 | 40 | 51 | 8 | > 5000 | 125 | 140 |

| ST235RAQ1N7_RZ | 1.7 | 5 | 62 | 82 | 159 | 22 | > 5000 | 35 | 600 |

| ST235RAQ1N8_RZ | 1.8 | 5 | 63 | 81 | 153 | 21 | > 5000 | 35 | 600 |

| ST235RAQ1N9_RZ | 1.9 | 5 | 63 | 103 | 149 | 22 | > 5000 | 35 | 600 |

| ST235RAQ2N0_RZ | 2.0 | 5,3 | 60 | 93 | 127 | 26 | > 5000 | 35 | 600 |

| ST235RAQ2N1_RZ | 2.1 | 5,3 | 47 | 72 | 94 | 19 | > 5000 | 48 | 600 |

| ST235RAQ2N2_RZ | 2.2 | 5,3 | 43 | 65 | 92 | 17 | > 5000 | 90 | 370 |

| ST235RAQ2N3_RZ | 2.3 | 5,3 | 43 | 64 | 85 | 17 | > 5000 | 110 | 280 |

| ST235RAQ2N4_RZ | 2.4 | 5,3 | 40 | 60 | 80 | 12 | > 5000 | 170 | 180 |

| ST235RAQ2N5_RZ | 2.5 | 5,3 | 31 | 45 | 59 | 11 | > 5000 | 210 | 140 |

| ST235RAQ2N8_RZ | 2.8 | 5,3 | 57 | 86 | 130 | 21 | > 5000 | 37 | 600 |

| ST235RAQ2N9_RZ | 2.9 | 5,3 | 59 | 89 | 136 | 21 | > 5000 | 37 | 600 |

| ST235RAQ3N0_RZ | 3.0 | 5,3,2 | 61 | 92 | 142 | 25 | > 5000 | 37 | 600 |

| ST235RAQ3N1_RZ | 3.1 | 5,3,2 | 63 | 100 | 148 | 27 | > 5000 | 37 | 600 |

| ST235RAQ3N2_RZ | 3.2 | 5,3,2 | 65 | 108 | 154 | 27 | > 5000 | 37 | 600 |

| ST235RAQ3N3_RZ | 3.3 | 5,3,2 | 68 | 116 | 160 | 28 | > 5000 | 37 | 600 |

| ST235RAQ3N4_RZ | 3.4 | 5,3,2 | 66 | 108 | 156 | 27 | > 5000 | 46 | 600 |

| ST235RAQ3N5_RZ | 3.5 | 5,3,2 | 67 | 110 | 156 | 27 | > 5000 | 46 | 600 |

| ST235RAQ3N6_RZ | 3.6 | 5,3,2 | 68 | 112 | 157 | 28 | > 5000 | 46 | 600 |

| ST235RAQ3N7_RZ | 3.7 | 5,3,2 | 68 | 112 | 157 | 28 | > 5000 | 46 | 600 |

| ST235RAQ3N8_RZ | 3.8 | 5,3,2 | 69 | 113 | 158 | 27 | > 5000 | 46 | 600 |

| ST235RAQ3N9_RZ | 3.9 | 5,3,2 | 69 | 114 | 158 | 30 | > 5000 | 46 | 600 |

| ST235RAQ4N0_RZ | 4.0 | 5,3,2 | 70 | 114 | 158 | 30 | > 5000 | 46 | 600 |

| ST235RAQ4N1_RZ | 4.1 | 5,3,2 | 71 | 115 | 159 | 27 | > 5000 | 46 | 600 |

| ST235RAQ4N2_RZ | 4.2 | 5,3,2 | 71 | 116 | 159 | 29 | > 5000 | 46 | 600 |

| ST235RAQ4N3_RZ | 4.3 | 5,3,2 | 62 | 100 | 136 | 28 | > 5000 | 48 | 600 |

| ST235RAQ4N4_RZ | 4.4 | 5,3,2 | 64 | 102 | 139 | 26 | > 5000 | 48 | 600 |

| ST235RAQ4N5_RZ | 4.5 | 5,3,2 | 65 | 104 | 141 | 26 | > 5000 | 48 | 600 |

| ST235RAQ4N6_RZ | 4.6 | 5,3,2 | 66 | 106 | 143 | 29 | > 5000 | 48 | 600 |

| ST235RAQ4N7_RZ | 4.7 | 5,3,2 | 67 | 108 | 146 | 28 | > 5000 | 48 | 600 |

| ST235RAQ4N8_RZ | 4.8 | 5,3,2 | 67 | 109 | 146 | 25 | > 5000 | 48 | 600 |

| ST235RAQ4N9_RZ | 4.9 | 5,3,2 | 67 | 110 | 147 | 25 | > 5000 | 48 | 600 |

| ST235RAQ5N0_RZ | 5.0 | 5,3,2 | 68 | 111 | 149 | 25 | > 5000 | 48 | 600 |

| ST235RAQ5N1_RZ | 5.1 | 5,3,2 | 68 | 111 | 150 | 27 | > 5000 | 48 | 600 |

| ST235RAQ5N2_RZ | 5.2 | 5,3,2 | 68 | 112 | 151 | 24 | > 5000 | 48 | 600 |

| ST235RAQ5N3_RZ | 5.3 | 5,3,2 | 67 | 110 | 144 | 26 | > 5000 | 57 | 600 |

| ST235RAQ5N4_RZ | 5.4 | 5,3,2 | 68 | 111 | 145 | 26 | > 5000 | 57 | 600 |

| ST235RAQ5N5_RZ | 5.5 | 5,3,2 | 68 | 111 | 145 | 26 | > 5000 | 57 | 600 |

| ST235RAQ5N6_RZ | 5.6 | 5,3,2 | 69 | 112 | 146 | 29 | > 5000 | 57 | 600 |

| ST235RAQ5N7_RZ | 5.7 | 5,3,2 | 69 | 112 | 146 | 27 | > 5000 | 57 | 600 |

| ST235RAQ5N8_RZ | 5.8 | 5,3,2 | 70 | 112 | 146 | 27 | > 5000 | 57 | 600 |

| ST235RAQ5N9_RZ | 5.9 | 5,3,2 | 70 | 112 | 146 | 28 | > 5000 | 57 | 600 |

| ST235RAQ6N0_RZ | 6.0 | 5,3,2 | 71 | 112 | 146 | 27 | > 5000 | 57 | 600 |

| ST235RAQ6N1_RZ | 6.1 | 5,3,2 | 71 | 112 | 146 | 28 | > 5000 | 57 | 600 |

| ST235RAQ6N2_RZ | 6.2 | 5,3,2 | 71 | 112 | 146 | 30 | > 5000 | 57 | 600 |

| ST235RAQ6N3_RZ | 6.3 | 5,3,2 | 72 | 113 | 146 | 27 | > 5000 | 57 | 600 |

| ST235RAQ6N4_RZ | 6.4 | 5,3,2 | 73 | 113 | 146 | 28 | > 5000 | 57 | 600 |

| ST235RAQ6N5_RZ | 6.5 | 5,3,2 | 73 | 114 | 147 | 27 | > 5000 | 57 | 600 |

| ST235RAQ6N6_RZ | 6.6 | 5,3,2 | 68 | 109 | 130 | 27 | > 5000 | 63 | 600 |

| ST235RAQ6N7_RZ | 6.7 | 5,3,2 | 69 | 109 | 132 | 27 | > 5000 | 63 | 600 |

| ST235RAQ6N8_RZ | 6.8 | 5,3,2 | 69 | 110 | 138 | 29 | > 5000 | 63 | 600 |

| ST235RAQ6N9_RZ | 6.9 | 5,3,2 | 69 | 110 | 138 | 26 | > 5000 | 63 | 600 |

| ST235RAQ7N0_RZ | 7.0 | 5,3,2 | 69 | 110 | 138 | 26 | > 5000 | 63 | 600 |

| ST235RAQ7N1_RZ | 7.1 | 5,3,2 | 69 | 110 | 138 | 28 | > 5000 | 63 | 600 |

| ST235RAQ7N2_RZ | 7.2 | 5,3,2 | 70 | 111 | 139 | 29 | > 5000 | 63 | 600 |

| ST235RAQ7N3_RZ | 7.3 | 5,3,2 | 70 | 111 | 139 | 27 | > 5000 | 63 | 600 |

| ST235RAQ7N4_RZ | 7.4 | 5,3,2 | 70 | 111 | 140 | 26 | > 5000 | 63 | 600 |

| ST235RAQ7N5_RZ | 7.5 | 5,3,2 | 71 | 112 | 140 | 26 | > 5000 | 63 | 600 |

| ST235RAQ7N6_RZ | 7.6 | 5,3,2 | 72 | 113 | 141 | 27 | > 5000 | 63 | 600 |

| ST235RAQ7N7_RZ | 7.7 | 5,3,2 | 70 | 109 | 135 | 27 | > 5000 | 70 | 600 |

| ST235RAQ7N8_RZ | 7.8 | 5,3,2 | 70 | 110 | 136 | 27 | > 5000 | 70 | 600 |

| ST235RAQ7N9_RZ | 7.9 | 5,3,2 | 71 | 110 | 136 | 28 | > 5000 | 70 | 600 |

| ST235RAQ8N0_RZ | 8.0 | 5,3,2 | 71 | 111 | 137 | 27 | > 5000 | 70 | 600 |

| ST235RAQ8N1_RZ | 8.1 | 5,3,2 | 71 | 112 | 137 | 29 | > 5000 | 70 | 600 |

| ST235RAQ8N2_RZ | 8.2 | 5,3,2 | 72 | 113 | 138 | 30 | > 5000 | 70 | 600 |

| ST235RAQ8N3_RZ | 8.3 | 5,3,2 | 72 | 113 | 138 | 28 | > 5000 | 70 | 600 |

| ST235RAQ8N4_RZ | 8.4 | 5,3,2 | 72 | 114 | 139 | 28 | > 5000 | 70 | 600 |

| ST235RAQ8N5_RZ | 8.5 | 5,3,2 | 73 | 115 | 139 | 29 | > 5000 | 70 | 600 |

| ST235RAQ8N6_RZ | 8.6 | 5,3,2 | 73 | 115 | 140 | 30 | > 5000 | 70 | 600 |

| ST235RAQ8N7_RZ | 8.7 | 5,3,2 | 73 | 116 | 140 | 29 | > 5000 | 70 | 600 |

| ST235RAQ8N8_RZ | 8.8 | 5,3,2 | 74 | 116 | 141 | 29 | > 5000 | 70 | 600 |

| ST235RAQ8N9_RZ | 8.9 | 5,3,2 | 74 | 117 | 141 | 30 | > 5000 | 70 | 600 |

| ST235RAQ9N0_RZ | 9.0 | 5,3,2 | 75 | 117 | 142 | 30 | > 5000 | 70 | 600 |

| ST235RAQ9N1_RZ | 9.1 | 5,3,2 | 75 | 118 | 142 | 28 | > 5000 | 70 | 600 |

| ST235RAQ9N2_RZ | 9.2 | 5,3,2 | 75 | 118 | 142 | 29 | > 5000 | 70 | 600 |

| ST235RAQ9N3_RZ | 9.3 | 5,3,2 | 71 | 105 | 142 | 27 | > 5000 | 73 | 600 |

| ST235RAQ9N4_RZ | 9.4 | 5,3,2 | 72 | 106 | 143 | 26 | > 5000 | 73 | 600 |

| ST235RAQ9N5_RZ | 9.5 | 5,3,2 | 73 | 108 | 144 | 26 | > 5000 | 73 | 600 |

| ST235RAQ9N6_RZ | 9.6 | 5,3,2 | 74 | 109 | 145 | 27 | > 5000 | 73 | 600 |

| ST235RAQ9N7_RZ | 9.7 | 5,3,2 | 75 | 110 | 146 | 27 | > 5000 | 73 | 600 |

| ST235RAQ9N8_RZ | 9.8 | 5,3,2 | 76 | 112 | 147 | 27 | > 5000 | 73 | 600 |

| ST235RAQ9N9_RZ | 9.9 | 5,3,2 | 77 | 113 | 148 | 28 | > 5000 | 73 | 600 |

| ST235RAQ10N_RZ | 10.0 | 5,3,2 | 77 | 113 | 148 | 28 | > 5000 | 73 | 600 |

| ST235RAQ11N_RZ | 11.0 | 5,3,2 | 68 | 100 | 134 | 29 | 4300 | 80 | 600 |

| ST235RAQ12N_RZ | 12.0 | 5,3,2 | 69 | 98 | 100 | 29 | > 5000 | 80 | 600 |

| ST235RAQ15N_RZ | 15.0 | 5,3,2 | 70 | 100 | 110 | 29 | > 5000 | 115 | 600 |

| ST235RAQ16N_RZ | 16.0 | 5,3,2 | 68 | 97 | 102 | 27 | 4800 | 120 | 600 |

| ST235RAQ18N_RZ | 18.0 | 5,3,2 | 68 | 95 | 98 | 29 | 4500 | 138 | 580 |

| ST235RAQ20N_RZ | 20.0 | 5,3,2 | 67 | 90 | 95 | 27 | 4100 | 163 | 530 |

| ST235RAQ22N_RZ | 22.0 | 5,3,2 | 67 | 88 | 83 | 28 | 4000 | 180 | 500 |

| ST235RAQ23N_RZ | 23.0 | 5,3,2 | 68 | 89 | - | 28 | 4000 | 180 | 500 |

| ST235RAQ24N_RZ | 24.0 | 5,3,2 | 63 | 85 | - | 27 | 3900 | 185 | 500 |

| ST235RAQ27N_RZ | 27.0 | 5,3,2 | 65 | 83 | 71 | 28 | 3700 | 193 | 480 |

| ST235RAQ30N_RZ | 30.0 | 5,3,2 | 62 | 76 | 62 | 27 | 3400 | 245 | 420 |

| ST235RAQ33N_RZ | 33.0 | 5,3,2 | 62 | 76 | - | 27 | 3400 | 275 | 400 |

| ST235RAQ36N_RZ | 36.0 | 5,3,2 | 60 | 72 | - | 27 | 3300 | 320 | 360 |

| ST235RAQ39N_RZ | 39.0 | 5,3,2 | 60 | 68 | - | 27 | 3100 | 375 | 350 |

| ST235RAQ43N_RZ | 43.0 | 5,3,2 | 55 | 54 | - | 27 | 3100 | 400 | 330 |

| ST235RAQ47N_RZ | 47.0 | 5,3,2 | 55 | 54 | - | 26 | 2700 | 400 | 330 |

| ST235RAQ51N_RZ | 51.0 | 5,3,2 | 55 | 54 | - | 26 | 2700 | 432 | 320 |

| ST235RAQ56N_RZ | 56.0 | 5,3,2 | 54 | - | - | 27 | 2600 | 690 | 240 |

| ST235RAQ62N_RZ | 62.0 | 5,3,2 | 54 | - | - | 27 | 2400 | 756 | 230 |

| ST235RAQ68N_RZ | 68.0 | 5,3,2 | 54 | - | - | 26 | 2300 | 943 | 210 |

| ST235RAQ72N_RZ | 72.0 | 5,3,2 | 54 | - | - | 27 | 2300 | 787 | 220 |

| ST235RAQ75N_RZ | 75.0 | 5,3,2 | 54 | - | - | 27 | 2200 | 882 | 220 |

| ST235RAQ82N_RZ | 82.0 | 5,3,2 | 51 | - | - | 26 | 2300 | 1057 | 190 |

| ST235RAQ91N_RZ | 91.0 | 5,3,2 | 48 | - | - | 26 | 2300 | 1119 | 190 |

| ST235RAQR10_RZ | 100.0 | 5,3,2 | 51 | - | - | 26 | 2000 | 1507 | 160 |

| ST235RAQR12_RZ | 120.0 | 5,3,2 | 46 | - | - | 26 | 1800 | 1600 | 160 |

Notes

- When ordering, please specify tolerance, termination and testing codes: e.g. ST235RAQ5N9JRZ.

- Inductance measured at 250 MHz using a Coilcraft SMD-F fixture in an Agilent/HP 4287 impedance analyzer with Coilcraft-provided correlation pieces.

- Tolerances in bold are stocked for immediate shipment.

- Q measured using an Agilent/HP 4991A with an Agilent/HP 16197 test fixture.

- SRF measured using an Agilent/HP 8722ES network analyzer and a Coilcraft SMD-D test fixture.

- DCR measured on a micro-ohmmeter and a Coilcraft CCF858 test fixture.

- Maximum current that can be applied at 125°C.

Tolerance:

- G = 2%

- H = 3%

- J = 5%

Termination:

- R = Matte tin over nickel over silver-platinum glass frit

- P = Tin-lead (63/37) over tin over nickel over silver platinum-glass frit

- Q = Tin-silver-copper (95.5/4/0.5) over tin over nickel over silver-platinum-glass frit

Testing:

- Z = Unscreened

- H = Group A screening per Coilcraft CP-SA-10001

Custom screening also available.

Environmental

Ambient temperature range:

–40°C to +125°C with Irms current.

Storage temperature range:

Component: –55°C to +140°C.

Tape and reel packaging: –40°C to +80°C.

Tape and reel packaging: –40°C to +80°C.

Maximum part temperature:

+140°C (ambient + temp rise).

Failures in Time (FIT) / Mean Time Between Failures (MTBF):

Performance curves

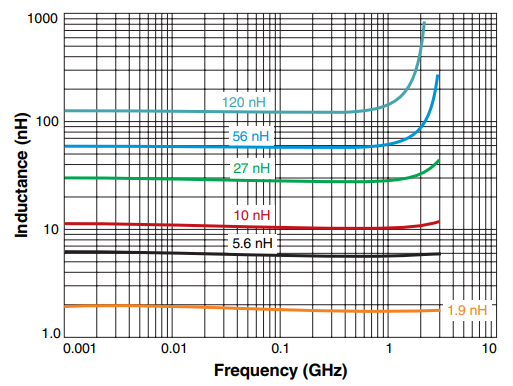

Typical L vs Frequency

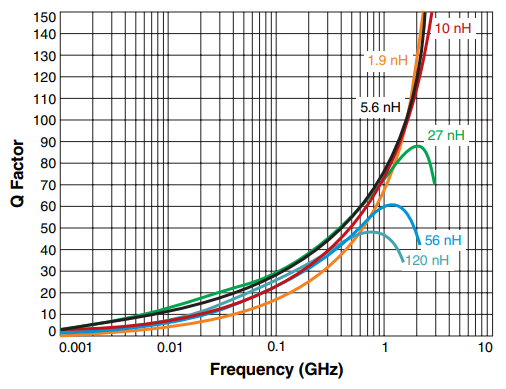

Typical Q vs Frequency

General specification

Core Material:

Ceramic

Weight:

0.7 – 1.0 mg

Packaging:

2000 or 10,000 per 7″ reel; Paper tape: 8 mm wide, 0.66 mm thick, 2 mm pocket spacing.

Temperature coefficient of inductance:

+25 to +125 ppm/°C.

Soldering/Washing

Moisture Sensitivity Level (MSL):

1 (unlimited floor life at <30°C / 85% relative humidity).

Resistance to soldering heat:

Max three 40 second reflows at +260°C, parts cooled to room temperature between cycles.

Refer to Soldering Coilcraft Components before soldering.

PCB Washing:

Tested to MIL-STD-202 Method 215 plus an additional aqueous wash.

See Doc787_PCB_Washing.pdf.

See Doc787_PCB_Washing.pdf.