3D Model

Datasheet

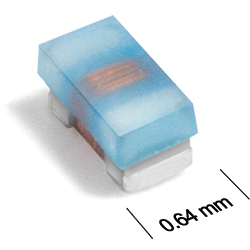

AR235RAA Series

Outgassing Compliant Chip Inductors

AR235RAA Series inductors use high temperature materials, allowing operation in ambient temperatures up to 155°C.

- Exceptionally high Q factors.

- Outstanding self-resonant frequency.

- Tight inductance tolerance.

- High temperature materials allow operation in ambient temperatures up to 155°C.

- Passes NASA low outgassing specifications.

- Standard tin-lead (Sn-Pb) terminations ensures the best possible board adhesion. Note: Nickel barrier termination (tin-lead over tin over nickel over silver-platinum-glass frit, termination code P) is recommended for hand soldering applications.

- Tin-lead (63/37) over tin over nickel over silver-platinumglass frit terminations. Other terminations are also available.

Specifications

Electrical specifications at 25°C.

Part is not compliant with MIL-STD-981 Family 50, Class S due to wire gauge.

| Part number 1 | Inductance (nH) 2 | Tolerance (%) | 900 MHz | 1.7 GHz |

Q min

@ 250 MHz 3 |

SRF min (GHz) 4 | DCR max (Ω) 5 | Imax (mA) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| L typ | Q typ 3 | L typ | Q typ 3 | |||||||

| AR235RAA1N0JPZ | 1.0 | 5 | 1.02 | 77 | 1.02 | 69 | 20 | > 5.00 | 0.045 | 600 |

| AR235RAA1N2JPZ | 1.2 | 5 | 1.17 | 28 | 1.17 | 38 | 12 | > 5.00 | 0.050 | 600 |

| AR235RAA1N8JPZ | 1.8 | 5 | 1.78 | 54 | 1.78 | 75 | 20 | > 5.00 | 0.070 | 600 |

| AR235RAA1N9JPZ | 1.9 | 5 | 1.72 | 68 | 1.74 | 82 | 20 | > 5.00 | 0.070 | 600 |

| AR235RAA2N0_PZ | 2.0 | 5,2 | 1.93 | 54 | 1.93 | 75 | 20 | > 5.00 | 0.070 | 600 |

| AR235RAA2N2_PZ | 2.2 | 5,2 | 2.19 | 59 | 2.23 | 100 | 20 | > 5.00 | 0.070 | 600 |

| AR235RAA2N4_PZ | 2.4 | 5,2 | 2.24 | 51 | 2.27 | 68 | 20 | > 5.00 | 0.068 | 600 |

| AR235RAA2N7_PZ | 2.7 | 5,2,1 | 2.58 | 42 | 2.6 | 61 | 16 | > 5.00 | 0.120 | 425 |

| AR235RAA3N3_PZ | 3.3 | 5,2,1 | 3.1 | 65 | 3.12 | 87 | 20 | > 5.00 | 0.066 | 600 |

| AR235RAA3N6_PZ | 3.6 | 5,2,1 | 3.56 | 45 | 3.62 | 71 | 20 | > 5.00 | 0.066 | 600 |

| AR235RAA3N9_PZ | 3.9 | 5,2,1 | 3.89 | 50 | 4.0 | 75 | 20 | > 5.00 | 0.066 | 600 |

| AR235RAA4N3_PZ | 4.3 | 5,2,1 | 4.19 | 47 | 4.3 | 71 | 20 | > 5.00 | 0.091 | 600 |

| AR235RAA4N7_PZ | 4.7 | 5,2,1 | 4.55 | 48 | 4.68 | 68 | 20 | 4.77 | 0.130 | 600 |

| AR235RAA5N1_PZ | 5.1 | 5,2,1 | 5.15 | 56 | 5.25 | 82 | 20 | 4.80 | 0.083 | 600 |

| AR235RAA5N6_PZ | 5.6 | 5,2,1 | 5.16 | 54 | 5.28 | 81 | 20 | 4.80 | 0.083 | 600 |

| AR235RAA6N2_PZ | 6.2 | 5,2,1 | 6.16 | 52 | 6.37 | 76 | 20 | 4.80 | 0.083 | 600 |

| AR235RAA6N8_PZ | 6.8 | 5,2,1 | 6.56 | 63 | 6.93 | 78 | 20 | 4.80 | 0.083 | 600 |

| AR235RAA7N5_PZ | 7.5 | 5,2,1 | 7.91 | 60 | 8.22 | 88 | 22 | 4.80 | 0.104 | 600 |

| AR235RAA8N2_PZ | 8.2 | 5,2,1 | 8.5 | 57 | 8.85 | 84 | 22 | 4.40 | 0.104 | 600 |

| AR235RAA8N7_PZ | 8.7 | 5,2,1 | 8.78 | 54 | 9.21 | 73 | 20 | 3.80 | 0.195 | 480 |

| AR235RAA9N0_PZ | 9.0 | 5,2,1 | 9.07 | 62 | 9.53 | 78 | 22 | 4.66 | 0.100 | 600 |

| AR235RAA9N5_PZ | 9.5 | 5,2,1 | 9.42 | 54 | 9.98 | 69 | 20 | 3.48 | 0.195 | 480 |

| AR235RAA10N_PZ | 10 | 5,2,1 | 9.8 | 50 | 10.1 | 67 | 21 | 3.68 | 0.195 | 480 |

| AR235RAA11N_PZ | 11 | 5,2,1 | 10.7 | 52 | 11.2 | 78 | 24 | 3.48 | 0.120 | 580 |

| AR235RAA12N_PZ | 12 | 5,2,1 | 11.9 | 53 | 12.7 | 71 | 24 | 3.60 | 0.120 | 580 |

| AR235RAA13N_PZ | 13 | 5,2,1 | 13.4 | 51 | 14.63 | 57 | 20 | 3.28 | 0.210 | 440 |

| AR235RAA15N_PZ | 15 | 5,2,1 | 14.6 | 55 | 15.5 | 77 | 22 | 3.10 | 0.172 | 500 |

| AR235RAA16N_PZ | 16 | 5,2,1 | 16.6 | 46 | 18.86 | 47 | 23 | 3.05 | 0.220 | 480 |

| AR235RAA18N_PZ | 18 | 5,2,1 | 18.3 | 57 | 20.28 | 62 | 24 | 2.68 | 0.230 | 420 |

| AR235RAA19N_PZ | 19 | 5,2,1 | 19.1 | 50 | 21.1 | 67 | 24 | 3.00 | 0.202 | 460 |

| AR235RAA20N_PZ | 20 | 5,2,1 | 20.7 | 52 | 23.66 | 53 | 24 | 2.90 | 0.250 | 400 |

| AR235RAA22N_PZ | 22 | 5,2,1 | 23.2 | 53 | 26.75 | 53 | 24 | 2.80 | 0.300 | 380 |

| AR235RAA23N_PZ | 23 | 5,2,1 | 23.8 | 49 | 26.9 | 64 | 24 | 2.72 | 0.300 | 400 |

| AR235RAA24N_PZ | 24 | 5,2,1 | 25.1 | 51 | 29.5 | 50 | 24 | 2.60 | 0.300 | 390 |

| AR235RAA27N_PZ | 27 | 5,2,1 | 28.7 | 49 | 33.5 | 63 | 24 | 2.48 | 0.298 | 380 |

| AR235RAA30N_PZ | 30 | 5,2,1 | 31.1 | 46 | 38.5 | 39 | 24 | 2.35 | 0.300 | 340 |

| AR235RAA33N_PZ | 33 | 5,2,1 | 34.9 | 31 | 41.74 | 32 | 20 | 2.30 | 0.300 | 340 |

| AR235RAA36N_PZ | 36 | 5,2,1 | 39.5 | 44 | 48.4 | 53 | 24 | 2.20 | 0.440 | 310 |

| AR235RAA39N_PZ | 39 | 5,3,2 | 41.7 | 47 | 50.23 | 45 | 24 | 2.10 | 0.550 | 200 |

| AR235RAA40N_PZ | 40 | 5,2,1 | 39 | 44 | 47.4 | 33 | 24 | 2.24 | 0.440 | 290 |

| AR235RAA47N_PZ | 47 | 5,2,1 | 50 | 38 | - | - | 20 | 2.10 | 0.830 | 150 |

Notes

- When ordering, specify tolerance, termination and screening codes: e.g. AR235RAA12NGPZ.

- Inductance measured at 250 MHz using a Coilcraft SMD-F test fixture and Coilcraft-provided correlation pieces with an Agilent/HP 4286A impedance analyzer or equivalent.

- For Q min: Q measured at 250 MHz using an Agilent/HP 4291A with an Agilent/HP 16197A test fixture or equivalents.

For Q typ: Q measured using an Agilent/HP 4291A with an Agilent/HP 16197A test fixture or equivalents. - SRF measured using an Agilent/HP 8753ES network analyzer and a Coilcraft CCF1232 test fixture.

- DCR measured on a Keithley 580 micro-ohmmeter and a Coilcraft CCF1010 test fixture.

Tolerance:

- F = 1%

- G = 2%

- J = 5%

Termination:

For hand soldering applications, the nickel barrier termination (tin-lead over tin over nickel over silver-platinum glass frit, termination code P) is recommended. Exposed gold or tin in the terminations migrates into the solder.- P = Tin-lead (63/37) over tin over nickel over silverplatinum-glass frit.

- C = Tin-lead (63/37) over gold over nickel over moly-mag.

- S = Tin-lead (63/37) over leach-resistant silver-platinumglass frit.

- A = Gold over nickel over moly-mag.

- L = Silver-palladium-platinum-glass frit.

Screening:

- Z = Unscreened

- H = Coilcraft CP-SA-10001 Group A

- 1 = EEE-INST-002 (Family 3) Level 1

- 2 = EEE-INST-002 (Family 3) Level 2

- 3 = EEE-INST-002 (Family 3) Level 3

- 4 = MIL-STD-981 (Family 50) Class B

- 5 = MIL-STD-981 (Family 50) Class S

- F = ESCC3201 (F4 operational life performed at 90°C)

- Screening performed to the document’s latest revision.

- Lot qualification (Group B) available.

- Testing T and U have been replaced with more detailed codes 4, 5, and 1, 2, 3, respectively. Codes T and U can still be used, if necessary. Custom testing also available.

- Country of origin restrictions available; prefix options G or F.

Environmental

Ambient temperature range:

–55°C to +125°C with Imax current.

Storage temperature range:

Component: –55°C to +155°C.

Packaging: –55°C to +80°C.

Packaging: –55°C to +80°C.

Maximum part temperature:

+155°C (ambient + temp rise).

Failures in Time (FIT) / Mean Time Between Failures (MTBF):

Performance curves

Typical L vs Frequency

Typical Q vs Frequency

General specification

Core Material:

Ceramic

Packaging:

2000 per 7″ reel Paper tape: 8 mm wide, 0.68 mm thick, 2 mm pocket spacing.

Temperature coefficient of inductance:

+25 to +155 ppm/°C.

Soldering/Washing

Moisture Sensitivity Level (MSL):

1 (unlimited floor life at <30°C / 85% relative humidity).

Resistance to soldering heat:

Max three 40 second reflows at +260°C, parts cooled to room temperature between cycles.

Refer to Soldering Coilcraft Components before soldering.