Datasheet

3D Model

ST612PND Series

High-Reliability Coupled Inductors

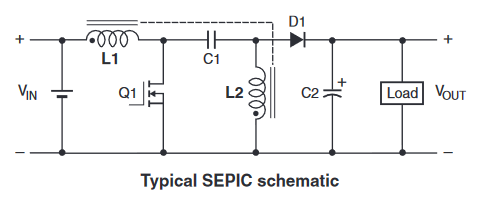

ST612PND Series high-reliability coupled inductors. Ideal for use in a variety of circuits including flyback, multi-output buck, SEPIC and Zeta. Can also be used as two single inductors connected in series or parallel or as a common mode choke.

- Materials allow for –55°C storage.

- Tight coupling (k ≥ 0.98) and 500 V isolation.

- High inductance and high efficiency.

- Excellent current handling.

- Matte tin over nickel over phos bronze terminations.

Specifications

Electrical specifications at 25°C.

For Flyback Applications

| Part number 1 | Inductance (µH) 2 | Tolerance (%) | DCR max (Ω) 3 |

Isolation Voltage (V) 4 |

Leakage Inductance (µH) |

|---|---|---|---|---|---|

| ST612PND472MLZ | 4.7 | 20 | 0.040 | 500 | 0.22 |

| ST612PND562MLZ | 5.6 | 20 | 0.046 | 500 | 0.23 |

| ST612PND682MLZ | 6.8 | 20 | 0.048 | 500 | 0.22 |

| ST612PND822MLZ | 8.2 | 20 | 0.055 | 500 | 0.34 |

| ST612PND103MLZ | 10 | 20 | 0.058 | 500 | 0.34 |

| ST612PND123MLZ | 12 | 20 | 0.062 | 500 | 0.36 |

| ST612PND153MLZ | 15 | 20 | 0.072 | 500 | 0.41 |

| ST612PND183MLZ | 18 | 20 | 0.080 | 500 | 0.37 |

| ST612PND223MLZ | 22 | 20 | 0.096 | 500 | 0.41 |

| ST612PND273MLZ | 27 | 20 | 0.12 | 500 | 0.43 |

| ST612PND333MLZ | 33 | 20 | 0.15 | 500 | 0.56 |

| ST612PND393MLZ | 39 | 20 | 0.16 | 500 | 0.64 |

| ST612PND473MLZ | 47 | 20 | 0.18 | 500 | 0.70 |

| ST612PND563MLZ | 56 | 20 | 0.19 | 500 | 0.76 |

| ST612PND683MLZ | 68 | 20 | 0.21 | 500 | 0.88 |

| ST612PND823MLZ | 82 | 20 | 0.28 | 500 | 0.85 |

| ST612PND104MLZ | 100 | 20 | 0.30 | 500 | 0.90 |

| ST612PND124KLZ | 120 | 10 | 0.41 | 500 | 1.3 |

| ST612PND154KLZ | 150 | 10 | 0.46 | 500 | 1.5 |

| ST612PND184KLZ | 180 | 10 | 0.51 | 500 | 0.93 |

| ST612PND224KLZ | 220 | 10 | 0.69 | 500 | 1.5 |

| ST612PND274KLZ | 270 | 10 | 0.90 | 500 | 1.2 |

| ST612PND334KLZ | 330 | 10 | 1.0 | 500 | 4.1 |

| ST612PND394KLZ | 390 | 10 | 1.1 | 500 | 1.6 |

| ST612PND474KLZ | 470 | 10 | 1.5 | 500 | 1.3 |

| ST612PND564KLZ | 560 | 10 | 1.7 | 500 | 2.7 |

| ST612PND684KLZ | 680 | 10 | 2.3 | 500 | 2.1 |

| ST612PND824KLZ | 820 | 10 | 2.6 | 500 | 2.4 |

| ST612PND105KLZ | 1000 | 10 | 2.9 | 500 | 4.3 |

For SEPIC Applications

| Part number 1 | Inductance (µH) 2 | Tolerance (%) | DCR max (Ω) 3 | SRF (MHz) 5 | Coupling coefficient |

Leakage Inductance (µH) |

Isat (A) 6 | Irms (A) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Typ | 10% drop | 20% drop | 30% drop | both windings 7 | one winding 8 | ||||||

| ST612PND472MLZ | 4.7 | 20 | 0.040 | 26.0 | 33.0 | 0.98 | 0.22 | 13.9 | 15.2 | 16.4 | 3.2 | 4.5 |

| ST612PND562MLZ | 5.6 | 20 | 0.046 | 24.0 | 30.0 | 0.98 | 0.23 | 13.4 | 14.9 | 15.7 | 2.9 | 4.1 |

| ST612PND682MLZ | 6.8 | 20 | 0.048 | 18.0 | 23.0 | 0.98 | 0.22 | 12.1 | 13.6 | 14.2 | 2.8 | 4.0 |

| ST612PND822MLZ | 8.2 | 20 | 0.055 | 16.0 | 20.0 | 0.98 | 0.34 | 10.3 | 11.5 | 12.2 | 2.8 | 3.9 |

| ST612PND103MLZ | 10 | 20 | 0.058 | 14.0 | 17.0 | 0.98 | 0.34 | 8.8 | 10.0 | 10.7 | 2.6 | 3.6 |

| ST612PND123MLZ | 12 | 20 | 0.062 | 12.0 | 15.0 | 0.98 | 0.36 | 8.2 | 9.2 | 9.7 | 2.5 | 3.5 |

| ST612PND153MLZ | 15 | 20 | 0.072 | 10.0 | 13.0 | 0.99 | 0.41 | 7.4 | 8.4 | 9.0 | 2.3 | 3.3 |

| ST612PND183MLZ | 18 | 20 | 0.080 | 9.6 | 12.0 | 0.99 | 0.37 | 6.5 | 7.4 | 7.9 | 2.2 | 3.1 |

| ST612PND223MLZ | 22 | 20 | 0.096 | 8.8 | 11.0 | 0.99 | 0.41 | 6.0 | 6.8 | 7.3 | 2.0 | 2.8 |

| ST612PND273MLZ | 27 | 20 | 0.12 | 8.0 | 10.0 | 0.99 | 0.43 | 5.8 | 6.6 | 7.0 | 1.8 | 2.5 |

| ST612PND333MLZ | 33 | 20 | 0.15 | 7.6 | 9.5 | 0.99 | 0.56 | 5.5 | 6.1 | 6.5 | 1.6 | 2.3 |

| ST612PND393MLZ | 39 | 20 | 0.16 | 6.8 | 8.5 | 0.99 | 0.64 | 4.7 | 5.3 | 5.6 | 1.5 | 2.2 |

| ST612PND473MLZ | 47 | 20 | 0.18 | 6.0 | 7.5 | 0.99 | 0.70 | 3.7 | 4.3 | 4.6 | 1.5 | 2.1 |

| ST612PND563MLZ | 56 | 20 | 0.19 | 5.6 | 7.0 | 0.99 | 0.76 | 3.6 | 4.2 | 4.5 | 1.4 | 2.0 |

| ST612PND683MLZ | 68 | 20 | 0.21 | 5.2 | 6.5 | 0.99 | 0.88 | 3.5 | 4.0 | 4.3 | 1.4 | 1.9 |

| ST612PND823MLZ | 82 | 20 | 0.28 | 4.0 | 5.0 | 0.99 | 0.85 | 3.3 | 3.7 | 4.0 | 1.2 | 1.7 |

| ST612PND104MLZ | 100 | 20 | 0.30 | 3.6 | 4.5 | >0.99 | 0.90 | 2.8 | 3.2 | 3.5 | 1.1 | 1.6 |

| ST612PND124KLZ | 120 | 10 | 0.41 | 3.4 | 4.3 | 0.99 | 1.3 | 2.6 | 2.9 | 3.2 | 0.96 | 1.4 |

| ST612PND154KLZ | 150 | 10 | 0.46 | 3.3 | 4.1 | >0.99 | 1.5 | 2.2 | 2.5 | 2.7 | 0.91 | 1.3 |

| ST612PND184KLZ | 180 | 10 | 0.51 | 3.2 | 4.0 | >0.99 | 0.93 | 2.1 | 2.4 | 2.6 | 0.86 | 1.2 |

| ST612PND224KLZ | 220 | 10 | 0.69 | 2.7 | 3.4 | >0.99 | 1.5 | 1.9 | 2.2 | 2.3 | 0.74 | 1.1 |

| ST612PND274KLZ | 270 | 10 | 0.90 | 2.5 | 3.1 | >0.99 | 1.2 | 1.7 | 1.9 | 2.1 | 0.65 | 0.92 |

| ST612PND334KLZ | 330 | 10 | 1.0 | 2.3 | 2.9 | 0.99 | 4.1 | 1.5 | 1.7 | 1.8 | 0.61 | 0.86 |

| ST612PND394KLZ | 390 | 10 | 1.1 | 2.2 | 2.7 | >0.99 | 1.6 | 1.4 | 1.6 | 1.7 | 0.58 | 0.82 |

| ST612PND474KLZ | 470 | 10 | 1.5 | 1.8 | 2.2 | >0.99 | 1.3 | 1.3 | 1.5 | 1.6 | 0.50 | 0.70 |

| ST612PND564KLZ | 560 | 10 | 1.7 | 1.6 | 2.0 | >0.99 | 2.7 | 1.2 | 1.3 | 1.5 | 0.47 | 0.67 |

| ST612PND684KLZ | 680 | 10 | 2.3 | 1.4 | 1.7 | >0.99 | 2.1 | 1.0 | 1.1 | 1.2 | 0.41 | 0.58 |

| ST612PND824KLZ | 820 | 10 | 2.6 | 1.1 | 1.4 | >0.99 | 2.4 | 0.90 | 1.0 | 1.2 | 0.39 | 0.55 |

| ST612PND105KLZ | 1000 | 10 | 2.9 | 1.0 | 1.3 | >0.99 | 4.3 | 0.85 | 0.95 | 1.1 | 0.37 | 0.52 |

Notes

- When ordering, please specify termination and screening codes: e.g. ST612PND105KLZ.

- Inductance shown for each winding, measured at 100 kHz, 0.1 Vrms, 0 Adc on an Agilent/HP 4284A LCR meter or equivalent. When leads are connected in parallel, inductance is the same value. When leads are connected in series, inductance is four times the value.

- DCR is for each winding. When leads are connected in parallel, DCR is half the value. When leads are connected in series, DCR is twice the value.

- Winding-to-winding and winding-to-core isolation 500 Vrms.

- SRF measured using an Agilent/HP 4191A or equivalent. When leads are connected in parallel, SRF is the same value.

- DC current at 25°C that causes the specified inductance drop from its value without current. It is the sum of the current flowing in both windings.

- Equal current when applied to each winding simultaneously that causes a 40°C temperature rise from 25°C ambient. This information is for reference only and does not represent absolute maximum ratings.

- Maximum current when applied to one winding that causes a 40°C temperature rise from 25°C ambient. This information is for reference only and does not represent absolute maximum ratings.

Refer to Doc 639 “Selecting Coupled Inductors for SEPIC Applications.”

Termination:

- L = Matte tin over nickel over phos bronze.

- S = Tin-lead (63/37) over tin over nickel over phos bronze.

Screening:

- Z = Unscreened

- Y = Unscreened (SLDC Option A)

- W = Unscreened (SLDC Option B)

- H = Group A screening per Coilcraft CP-SA-10001

- G= Coilcraft CP-SA-10001 Group A (SLDC Option A)

- D = Coilcraft CP-SA-10001 Group A (SLDC Option B)

Custom screening also available.

Environmental

Ambient temperature range:

–40°C to +125°C with Irms current.

Storage temperature range:

Component: –55C to +165°C.

Tape and reel packaging: –55°C to +80°C.

Tape and reel packaging: –55°C to +80°C.

Maximum part temperature:

+165°C (ambient + temp rise).

Failures in Time (FIT) / Mean Time Between Failures (MTBF):

Performance curves

Typical L vs Current

Typical L vs Frequency

Schematics

General specification

Core Material:

Ferrite

Weight:

3.8 g – 4.6 g

Packaging:

500/13′′ reel; Plastic tape: 24 mm wide, 0.4 mm thick, 16 mm pocket spacing, 8.1 mm pocket depth.

Soldering/Washing

Moisture Sensitivity Level (MSL):

1 (unlimited floor life at <30°C / 85% relative humidity).

Resistance to soldering heat:

Max three 40 second reflows at +260°C, parts cooled to room temperature between cycles.

Refer to Soldering Coilcraft Components before soldering.