Datasheet

3D Model

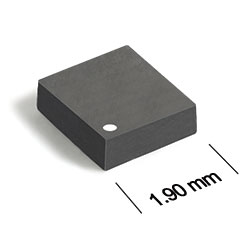

MS322PZA Series

High Reliability Power Inductors

MS322PZA Series features soft saturation making them ideal for VRM/VRD applications.

- High temperature materials allow operation in ambient temperatures up to 155°C.

- Tin-lead (Sn-Pb) termination for the best possible board adhesion.

- Lowest profile, ultra-miniature, shielded power inductor.

- Special construction allows it to pass vibration testing to 80 G and shock testing to 1000 G.

- Tin-lead (63/37) over copper terminations.

Specifications

Electrical specifications at 25°C.

| Part number 1 |

Inductance (µH)

2

(Tolerance: ±20%) |

DCR (Ω) 3 | SRF (MHz) 4 | Isat (A) 5 | Irms (A) 6 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| typ | max | min | typ | 10% drop | 20% drop | 30% drop | 20°C rise | 40°C rise | ||

| MS322PZA102MSZ | 1.0 | 0.15 | 0.17 | 136 | 170 | 0.71 | 1.0 | 1.2 | 0.91 | 1.2 |

| MS322PZA222MSZ | 2.2 | 0.28 | 0.31 | 88.0 | 110 | 0.49 | 0.69 | 0.78 | 0.71 | 0.95 |

| MS322PZA332MSZ | 3.3 | 0.46 | 0.51 | 70.0 | 88.0 | 0.42 | 0.56 | 0.66 | 0.55 | 0.72 |

| MS322PZA472MSZ | 4.7 | 0.67 | 0.73 | 54.0 | 68.0 | 0.31 | 0.44 | 0.52 | 0.50 | 0.66 |

| MS322PZA562MSZ | 5.6 | 0.75 | 0.83 | 49.0 | 61.0 | 0.30 | 0.43 | 0.50 | 0.46 | 0.60 |

| MS322PZA682MSZ | 6.8 | 0.92 | 1.0 | 45.0 | 57.0 | 0.26 | 0.35 | 0.41 | 0.40 | 0.52 |

| MS322PZA822MSZ | 8.2 | 1.1 | 1.2 | 41.0 | 51.0 | 0.24 | 0.33 | 0.39 | 0.37 | 0.49 |

| MS322PZA103MSZ | 10 | 1.3 | 1.4 | 36.0 | 45.0 | 0.24 | 0.31 | 0.37 | 0.35 | 0.44 |

| MS322PZA153MSZ | 15 | 2.0 | 2.2 | 29.6 | 37.0 | 0.19 | 0.25 | 0.29 | 0.27 | 0.35 |

| MS322PZA223MSZ | 22 | 2.8 | 3.1 | 24.4 | 30.5 | 0.15 | 0.21 | 0.24 | 0.24 | 0.31 |

| MS322PZA333MSZ | 33 | 4.5 | 4.9 | 19.2 | 24.0 | 0.11 | 0.15 | 0.18 | 0.16 | 0.21 |

| MS322PZA473MSZ | 47 | 5.6 | 6.2 | 15.6 | 19.5 | 0.090 | 0.13 | 0.16 | 0.16 | 0.21 |

| MS322PZA563MSZ | 56 | 6.7 | 7.3 | 13.2 | 16.5 | 0.085 | 0.12 | 0.15 | 0.15 | 0.20 |

| MS322PZA683MSZ | 68 | 8.5 | 9.4 | 12.8 | 16.0 | 0.080 | 0.12 | 0.14 | 0.12 | 0.16 |

| MS322PZA823MSZ | 82 | 9.3 | 10.2 | 10.8 | 13.5 | 0.065 | 0.090 | 0.12 | 0.13 | 0.17 |

| MS322PZA104MSZ | 100 | 11.1 | 12.3 | 10.4 | 13.0 | 0.065 | 0.090 | 0.12 | 0.10 | 0.14 |

Notes

- When ordering, please specify screening code: e.g. MS322PZA104MSZ.

- Inductance tested at 100 kHz, 0.1 Vrms, 0 Adc.

- DCR measured on a micro-ohmmeter.

- SRF measured using Agilent/HP 4395A or equivalent.

- DC current at 25°C that causes the specified inductance drop from its value without current.

- Current that causes the specified temperature rise from 25°C ambient. This information is for reference only and does not represent absolute maximum ratings.

Screening:

- Z = Unscreened

- Y = Unscreened (SLDC Option A)

- W = Unscreened (SLDC Option B)

- H = Group A screening per Coilcraft CP-SA-10001

- G= Coilcraft CP-SA-10001 Group A (SLDC Option A)

- D = Coilcraft CP-SA-10001 Group A (SLDC Option B)

Environmental

Ambient temperature range:

–55°C to +105°C with Irms current.

Storage temperature range:

Component: –55°C to +155°C.

Tape and reel packaging: –55°C to +80°C.

Tape and reel packaging: –55°C to +80°C.

Maximum part temperature:

+155°C (ambient + temp rise).

Failures in Time (FIT) / Mean Time Between Failures (MTBF):

Performance curves

Typical L vs Frequency

Typical L vs Current

Physical characteristics

Note: Earlier production parts may not be marked with a dot.

Tape and Reel specification

General specification

Core Material:

Composite

Weight:

9 – 13 mg

Packaging:

2000/7′′ reel Plastic tape: 8 mm wide, 0.28 mm thick, 4 mm pocket spacing, 0.76 mm pocket depth

Soldering/Washing

Moisture Sensitivity Level (MSL):

1 (unlimited floor life at <30°C / 85% relative humidity).

Resistance to soldering heat:

Max three 40 second reflows at +260°C, parts cooled to room temperature between cycles.

Refer to Soldering Coilcraft Components before soldering.