3D Model

Datasheet

ST450FRC Series

Common Mode Chokes

ST450FRC Series designed for common mode noise suppression on CAN or CAN FD in automotive or general industrial automation applications.

- Can be used for FlexRay automotive bus system.

- 50% lower DCR and higher current handling than other CANbus chokes in the market.

- Filters a broad frequency range of common mode noise.

- Low profile 1812 footprint: 4.95 × 3.18 × 3.0 mm.

- Matte tin over nickel over silver-palladium-glass frit terminations.

Specifications

Electrical specifications at 25°C.

| Part number 1 | Lines |

Inductance (µH)

2

(Tolerance: ±30%) |

Irms (mA) 3 | DCR max (Ω) 4 |

Isolation Voltage (Vrms) 5 |

|---|---|---|---|---|---|

| ST450FRC113NRZ | 2 | 11 | 460 | 0.27 | 250 |

| ST450FRC223NRZ | 2 | 22 | 400 | 0.40 | 250 |

| ST450FRC513NRZ | 2 | 51 | 300 | 0.59 | 250 |

| ST450FRC104NRZ | 2 | 100 | 260 | 1.0 | 250 |

Notes

- When ordering, please specify termination code: e.g. ST450FRC104NRZ.

- Inductance is per winding, measured at 100 kHz, 0.1 Vrms, 0 Adc using an Agilent/ HP 4263B LCR meter and a Coilcraft CCF 1113 fixture.

- Current per winding that causes a 25°C rise from +125°C ambient.

- DCR is specified per winding, measured at on a Keithley 580 microohmmeter and a Coilcraft CCF 858 fixture.

- Winding to winding isolation (hipot) tested for one minute.

Termination:

- R = Matte tin over nickel over silver-platinum glass frit.

- P = Tin-lead (63/37) over tin over nickel over silver-platinum-glass frit.

- Q = Tin-silver-copper (95.5/4/0.5) over tin over nickel over silver-platinum-glass frit.

Environmental

Ambient temperature range:

–40°C to +125°C with Irms current.

Storage temperature range:

Component: –55°C to +150°C.

Tape and reel packaging: –55°C to +80°C.

Tape and reel packaging: –55°C to +80°C.

Maximum part temperature:

+150°C.

Failures in Time (FIT) / Mean Time Between Failures (MTBF):

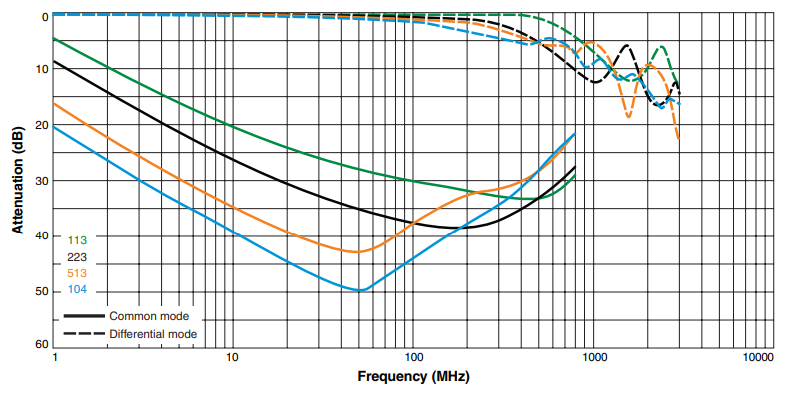

Performance curves

Typical Attenuation (Ref: 50 Ohms)

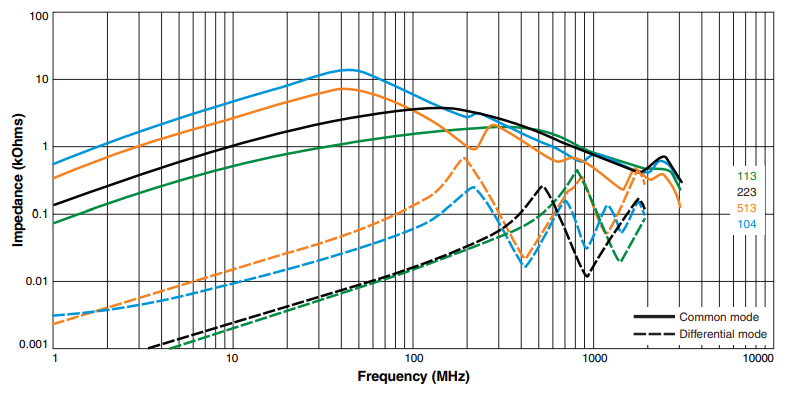

Typical Impedance vs Frequency

General specification

Core Material:

Ferrite

Weight:

120 – 130 mg

Packaging:

600/7″ reel; 2200/13″ reel; Plastic tape: 12 mm wide, 0.30 mm thick, 8 mm pocket spacing, 3.05 mm pocket depth.

Soldering/Washing

Moisture Sensitivity Level (MSL):

1 (unlimited floor life at <30°C / 85% relative humidity).

Resistance to soldering heat:

Max three 40 second reflows at +260°C, parts cooled to room temperature between cycles.

Refer to Soldering Coilcraft Components before soldering.

PCB Washing:

Tested to MIL-STD-202 Method 215 plus an additional aqueous wash. See Doc787_PCB_Washing.pdf.