Datasheet

3D Models

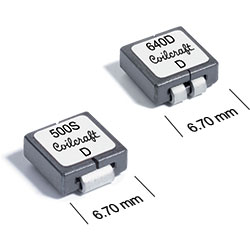

ST515PMM, ST515PMD Series

Power Inductor for Critical Applications

ST515PMM and ST515PMD Series are designed for high-speed switch mode applications.

- Can be used as a 1:1 transformer or in SEPIC applications.

- Matte tin over nickel over copper. Other terminations available at additional cost.

Specifications

Electrical specifications at 25°C.

Single Conductor

| Part number 1 |

Inductance (µH)

2

(Tolerance: ±20%) |

DCR ± 5% (mΩ) 3 | SRF ref (GHz) 4 | Isat (A) 5 | Irms (A) 6 |

|---|---|---|---|---|---|

| ST515PMM500MLZ | 0.050 | 0.123 | 3.80 | 50 | 40 |

| ST515PMM640MLZ | 0.064 | 0.123 | 3.65 | 32 | 40 |

| ST515PMM820MLZ | 0.082 | 0.123 | 3.75 | 22 | 40 |

| ST515PMM101MLZ | 0.100 | 0.123 | 3.75 | 20 | 40 |

Dual Conductor

| Part number 1 | Leads connected in parallel | Leads connected in series | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

L (µH)

2

(±20%) |

DCR ± 5% (mΩ) 3 | SRF ref (GHz) 4 | Isat (A) 5 | Irms (A) 6 |

L (µH)

2

(±20%) |

DCR max (mΩ) 3 | SRF ref (GHz) 4 | Isat (A) 5 | Irms (A) 6 | |

| ST515PMD500MLZ | 0.050 | 0.209 | 3.75 | 50 | 38 | 0.188 | 1.000 | 1.5 | 21 | 17 |

| ST515PMD640MLZ | 0.064 | 0.209 | 3.65 | 32 | 38 | 0.272 | 1.000 | 1.3 | 14 | 17 |

| ST515PMD820MLZ | 0.082 | 0.209 | 3.75 | 22 | 38 | 0.350 | 1.000 | 1.2 | 11 | 17 |

| ST515PMD101MLZ | 0.100 | 0.209 | 3.75 | 20 | 38 | 0.400 | 1.000 | 0.95 | 8 | 17 |

Notes

- When ordering, specify conductors, termination and screening codes: e.g. ST515PMM101MLZ.

- Inductance tested at 100 kHz, 0.1 Vrms using an Agilent/HP 4263B LCR meter or equivalent.

- DCR is measured on a micro-ohmmeter at points indicated in the diagram.

- This information is for design purposes only and shall not be tested during screening.

- DC current at 25°C that causes a 20% (typ) inductance drop from its value without current.

- Current that causes the specified temperature rise from 25°C ambient. This information is for reference only and does not represent absolute maximum ratings.

Due to the design of this component, DWV and IR shall not be specified or tested.

Termination:

- L = Matte tin over nickel over copper.

- T = Tin-silver-copper (95.5/4/0.5). (Special order, added cost)

- S = Tin-lead (63/37). (Special order, added cost)

Screening:

- Z = Unscreened

- Y = Unscreened (SLDC Option A)

- W = Unscreened (SLDC Option B)

- H = Group A screening per Coilcraft CP-SA-10001

- G= Coilcraft CP-SA-10001 Group A (SLDC Option A)

- D = Coilcraft CP-SA-10001 Group A (SLDC Option B)

Custom screening also available.

Environmental

Ambient temperature range:

–40°C to +85°C with (40°C rise) Irms current.

Storage temperature range:

Component: –55°C to +125°C.

Tape and reel packaging: –55°C to +80°C.

Tape and reel packaging: –55°C to +80°C.

Maximum part temperature:

+125°C (ambient + temp rise). Derating.

Failures in Time (FIT) / Mean Time Between Failures (MTBF):

Performance curves

Typical L vs Current - Single Conductor

Typical L vs Current - Dual Conductor

Typical L vs Frequency - Single Conductor

Typical L vs Frequency - Dual Conductor

Typical Temperature Rise vs Current

Current Derating

Physical characteristics

Dimensions - Single Conductor

Dimensions - Dual Conductor

Notes:

1. Dimensions are in inches/mm.

2. Dimensions are before optional solder application. For maximum overall dimensions including solder, add 0.0025 in / 0.064 mm to the length, and 0.006 in / 0.15 mm to the height.

3. Top surface is divided by a slot which should be considered when handled by a vacuum pick-and-place process.

Dimensions - Dual Conductor

Notes:

1. Dimensions are in inches/mm.

2. Dimensions are before optional solder application. For maximum overall dimensions including solder, add 0.0025 in / 0.064 mm to the length, and 0.006 in / 0.15 mm to the height.

3. Top surface is divided by a slot which should be considered when handled by a vacuum pick-and-place process.

General specification

Core Material:

Ferrite

Weight:

0.44 - 0.47 g

Packaging:

500/7″ reel; Plastic tape: 16 mm wide, 0.33 mm thick, 12 mm pocket spacing, 3.12 mm pocket depth.

Soldering/Washing

Moisture Sensitivity Level (MSL):

1 (unlimited floor life at <30°C / 85% relative humidity).

Resistance to soldering heat:

Max three 40 second reflows at +260°C, parts cooled to room temperature between cycles.

Refer to Soldering Coilcraft Components before soldering.