Datasheet

3D Model

Specifications

| Part number 1 | Lines |

Common mode peak impedance (kΩ) |

Cutoff frequency (MHz) 2 |

Common mode attenuation typ (dB) |

Inductance min (nH) 3 |

Irms (mA) 4 | DCR max (Ω) 5 |

Isolation Voltage (Vrms) 6 |

||

|---|---|---|---|---|---|---|---|---|---|---|

| 10 MHz | 100 MHz | 500 MHz | ||||||||

| CP336FRA902MAZ | 2 | 2.06 @ 810 MHz | 470 | 8.7 | 18.7 | 30.5 | 413 | 500 | 0.65 | 250 |

Notes

- When ordering, please specify termination and testing codes: e.g. CP336FRA902MAZ.

- Frequency at which the differential mode attenuation equals −3 dB.

- Inductance is measured on an Agilent 4286A (or equivalent) with a Coilcraft SMD-A test fixture using the listed correlation.

- Current per winding that causes a 20°C rise from 25°C ambient.

- DCR is measured on a Keithley 580 Micro-ohmmeter (or equivalent) with a Coilcraft CCF858 test fixture.

- Winding to winding isolation (hipot) tested for one minute.

Termination:

- A = Gold over nickel over silver-palladium-glass frit.

- C = Tin-lead over gold over nickel over silver-palladiumglass frit. (Special order, added cost)

- F = Tin-silver-copper over gold over nickel over silverpalladium-glass frit. (Special order, added cost)

Testing:

- Z = Unscreened

- H = Group A screening per Coilcraft CP-SA-10001

Custom screening also available.

Environmental

Ambient temperature range:

–40°C to +85°C with Irms current.

Storage temperature range:

Component: –55°C to +105°C.

Tape and reel packaging: –55°C to +80°C.

Tape and reel packaging: –55°C to +80°C.

Maximum part temperature:

+105°C (ambient + temp rise).

Failures in Time (FIT) / Mean Time Between Failures (MTBF):

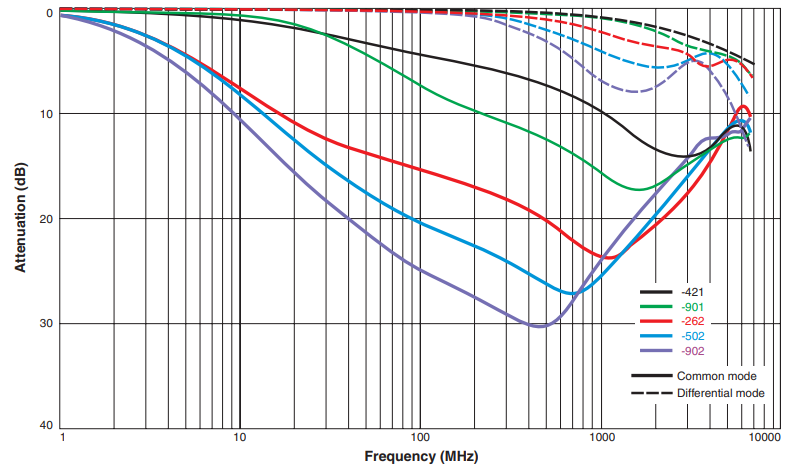

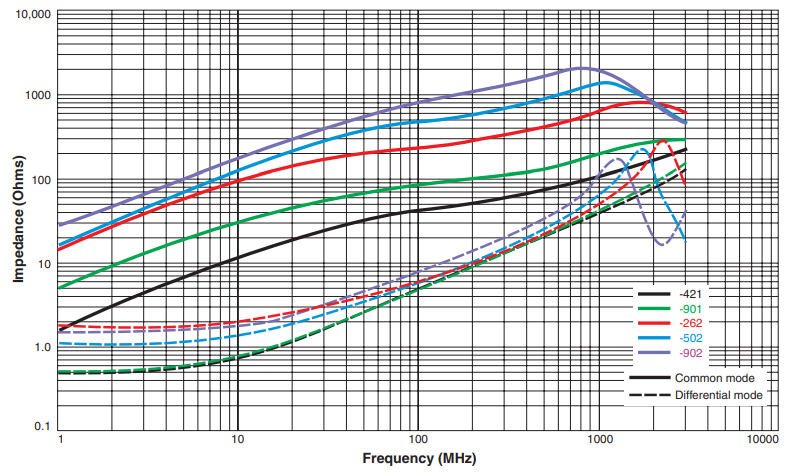

Performance curves

Typical Attenuation (Ref: 50 Ohms)

Typical Impedance vs Frequency

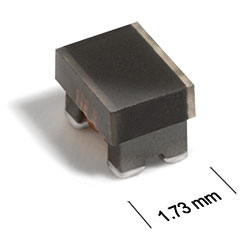

General specification

Core Material:

Ferrite

Weight:

14.9 – 20.0 mg

Packaging:

2000 per 7″reel; Plastic tape: 8 mm wide, 0.23 mm thick, 4 mm pocket spacing, 1.14 mm pocket depth.

Soldering/Washing

Moisture Sensitivity Level (MSL):

1 (unlimited floor life at <30°C / 85% relative humidity).

Resistance to soldering heat:

Max three 40 second reflows at +260°C, parts cooled to room temperature between cycles.

Refer to Soldering Coilcraft Components before soldering.